How to Dry Pitaya Flower by KINKAI Heat Pump Dehydrator Machine?

| Application | Fruits/Vegetabless/Agriculturals/Herbs/Seafoods/Meat/Wooden… |

| Power | 220V/380V, 50Hz/60Hz (Customized) |

| Capacity | 100-3500KGS |

| Temperature | 15-75℃ |

| Dehydration Capacity | 6-120L/H |

| Advantages | * 80% Electricity energy saving * Intelligent PLC Control System (Temperature, Humidity, Time) * High drying capacity 100-3500kgs per batch * Easy installation & operation * Widely Application & Customized |

Pitaya Flower

Pitaya flowers can either be cooked with or without meat or made into tea. It is a real natural healthy food but difficult to store, transport, and process due to its high content, even more than 86%. Only a very little of fresh pitaya flower is eaten by people in Guangdong or made into soup. Most of the pitaya flower is dried. Some dried pitaya flowers available in the current market are dusky, poor quality, and easy to ferment. Some are smoked by sulfur so much that its safety can’t be guaranteed. Guangzhou Kaineng Electric Equipment Co., Ltd. has launched a new-typed heat pump pitaya flower dryer which is energy-saving, environmentally efficient, and can produce high-quality dried pitaya flower.

How to Dry Pitaya Flower by KINKAI Heat Pump Dehydrator Machine?

The pitaya flower drying base, located in Huadu District, Guangzhou, has the capability of curing 10 tons of pitaya flower in each flowering season based on customers’ yield. It used to dry pitaya flowers with coal-burning boilers which produced serious pollution, occupied a larger area, and needed a lot of manual operation, and had to continuously buy coals. A large quantity of heat was wasted as the coal was burning. Furthermore, it could only cure a small amount of fresh pitaya flower at a time.

Customers decided to use our KINKAI pitaya flower dryer. It planned to dry 3 tons of fresh pitaya flowers at a time in the beginning. Based on this, we designed a drying cabinet with a volume of 120 cubic meters to meet its requirement. The drying cabinet we provided was large enough to contain 4 tons of fresh pitaya flowers. So, we provided 2 sets of KINKAI machines (JK12RD) which are able to process 3.5 tons of fresh pitaya flowers as required by customers. After several repeating tests, it only takes 20 hours for KINKAI dryers to dry out 3.5 tons of fresh pitaya flowers. Pictures show that the pitaya flower dried by a KINKAI dryer is more lustrous than that dried by burning wood or coal. KINKAI dryer facilitates you to produce energy-saving, environmental, pollution-free, healthy, and green food.

So, the KINKAI dryer is worthy of your trust.

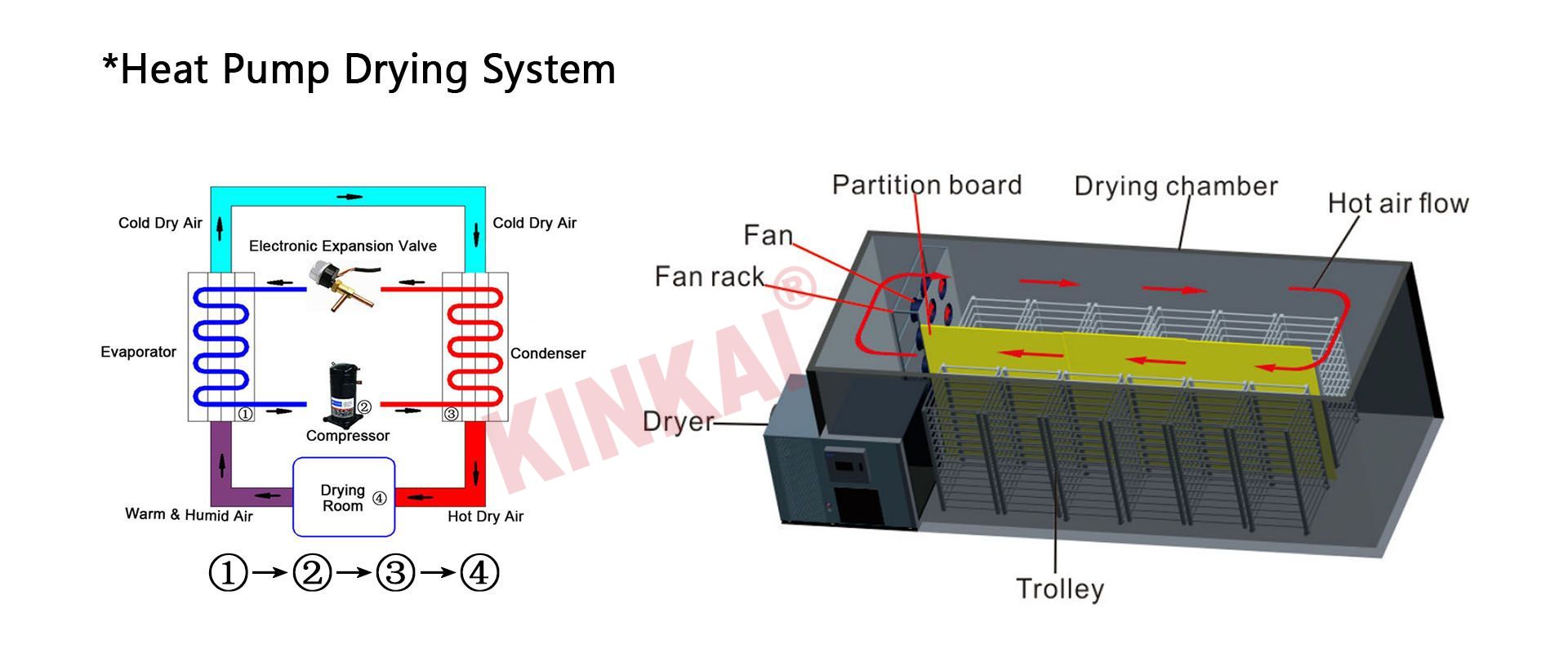

Working Principle of Heat Pump Dryer Machine

Use electric energy to supply power, absorb the air in the surrounding environment through heat pump technology, convert the air source into a heat source, convert 1 kWh of electric energy into 4 parts of air heat energy, save 75% of electricity, and play a high-efficiency, energy-saving, and environmentally friendly role.

Production of Heat Pump Dryer Machine

China’s first heat pump food dryer manufacturer, rich production experience, cost-effective supply chain, stable product quality and excellent after-sales service, providing customers with worry-free purchases.

Loading Heat Pump Dryer Machine-Sea transport

It is packed in a wooden box, stably protects the machine, complete accessories, easy to install, provides installation videos and product instruction manuals, supports online technical support, and can also go to the site to guide installation and use.