How to Dry Peppers by KINKAI Heat Pump Dehydrator Machine?

| Application | Fruits/Vegetabless/Agriculturals/Herbs/Seafoods/Meat/Wooden… |

| Power | 220V/380V, 50Hz/60Hz (Customized) |

| Capacity | 100-3500KGS |

| Temperature | 15-75℃ |

| Dehydration Capacity | 6-120L/H |

| Advantages | * 80% Electricity energy saving * Intelligent PLC Control System (Temperature, Humidity, Time) * High drying capacity 100-3500kgs per batch * Easy installation & operation * Widely Application & Customized |

Pepper

It is the rainy season when peppers are harvested. The autumn rainfall frequency is usually 70-80%, and even higher. In this situation, peppers will soon mildew and rot if not dried in time.

After a long time of research, we have developed a pepper dryer with many obvious advantages. Traditional dryers can only dry a small number of peppers at a time but consume a lot of energy, resulting in serious environmental pollution. Furthermore, they can’t guarantee the safety and the running cost is very high due to special care. The new-typed pepper dryer has higher thermal efficiency which is up to 400% and its operational cost is only one-third of that of gas or coal-burning dryers.

KINKAI dryer can generate cold wind as running, which will improve the working environment in the workshop. We not only provide customized dryers in different types and sizes but also modify the dryers to meet your requirements.

How to Dry Peppers by KINKAI Heat Pump Dehydrator Machine?

Drying peppers by phase is the best practice at present.

In the first phase, dry the chili (pepper) to reduce its moisture content from 75-80% to 50%, and then pile them up to sweat.

In the second phase, dry the sweated pepper. Piling pepper up for sweating is a very important step in the pepper drying process and has a great impact on the quality and quantity of dried peppers and drying time.

Pepper becomes soft and inflated in the drying process. Piling peppers up for sweating plays a great role in improving the quality of dried pepper. It will force pepper oil to permeate toward the pepper’s surface to make the color of dried peppers uniform, red, and smooth and to make water well-distributed.

It only takes 20-40 hours to dry up pepper, and the number of yellow peppers is decreased.

If not, it takes 63 hours to dry 1,000 kilograms of peppers at 40-60°C. Don’t stir pepper too much in the second phase. Otherwise, the damage rate will rise, resulting in a decline in the sales price. Drying time varies with the quantity and type of pepper.

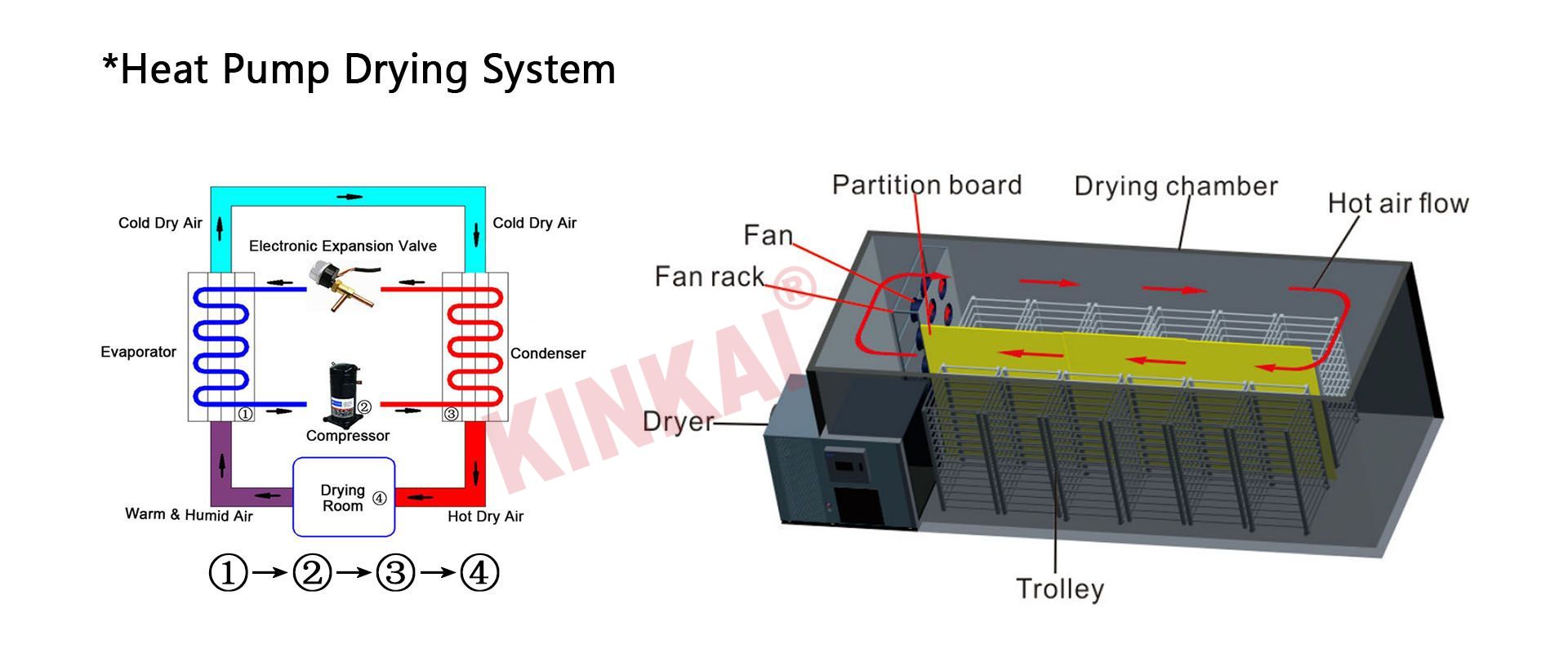

Working Principle of Heat Pump Dryer Machine

Use electric energy to supply power, absorb the air in the surrounding environment through heat pump technology, convert the air source into a heat source, convert 1 kWh of electric energy into 4 parts of air heat energy, save 75% of electricity, and play a high-efficiency, energy-saving, and environmentally friendly role.

Production of Heat Pump Dryer Machine

China’s first heat pump food dryer manufacturer, rich production experience, cost-effective supply chain, stable product quality and excellent after-sales service, providing customers with worry-free purchases.

Loading Heat Pump Dryer Machine-Sea transport

It is packed in a wooden box, stably protects the machine, complete accessories, easy to install, provides installation videos and product instruction manuals, supports online technical support, and can also go to the site to guide installation and use.