How to dry Cordyceps Militaris by KINKAI Heat Pump Dehydrator Machine?

| Application | Fruits/Vegetabless/Agriculturals/Herbs/Seafoods/Meat/Wooden… |

| Power | 220V/380V, 50Hz/60Hz (Customized) |

| Capacity | 100-3500KGS |

| Temperature | 15-75℃ |

| Dehydration Capacity | 6-120L/H |

| Advantages | * 80% Electricity energy saving * Intelligent PLC Control System (Temperature, Humidity, Time) * High drying capacity 100-3500kgs per batch * Easy installation & operation * Widely Application & Customized |

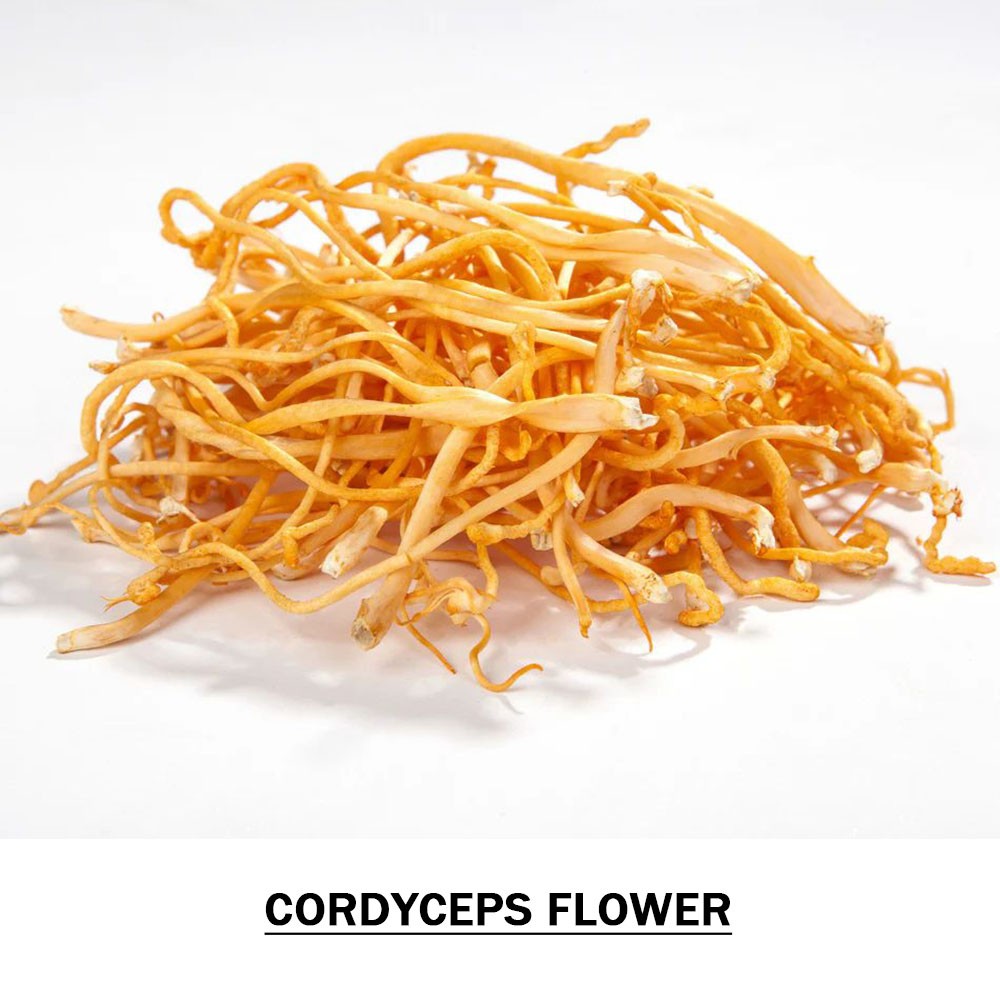

Cordyceps Militaris

Cordyceps flower, or Bei Dong Chong (the “Northern winter worms” ), is a valuable medicinal fungus in modern times. It mainly grows in North China. Abounding in protein and amino acids, it contains more than 30 microelements necessary for the human body. It is known as a first-class tonic. The traditional method uses electricity for heat, boilers, and microwaves. In actual use, this method costs highly, increasing production costs and being unhelpful in enlarging sales. In addition, it takes about 24 hours to dry cordyceps flower up, producing an unsatisfying color, which annoys most enterprises. Accordingly, this method is not used widely. Some enterprises even directly dry cordyceps flowers

using sunlight.

How to Dry Cordyceps flower by KINKAI Heat Pump Dehydrator Machine?

Phase 1

Moisture content in fresh cordyceps flowers is up to 78%. Set the temperature at 35 ° C to dry the cordyceps flower for 3–4 hours to remove some water.

Phase 2

Raise the temperature to 45° C to dry the cordyceps flower with 65% moisture content for 5 hours. After that, the moisture content is reduced down to 30%. The cordyceps flower looks dry.

Phase 3

Raise the temperature to 55 ° C and dry the cordyceps flower for 3 hours until they can be crumbed to pieces, and then halt the dryer to pack up the dried product for storage.

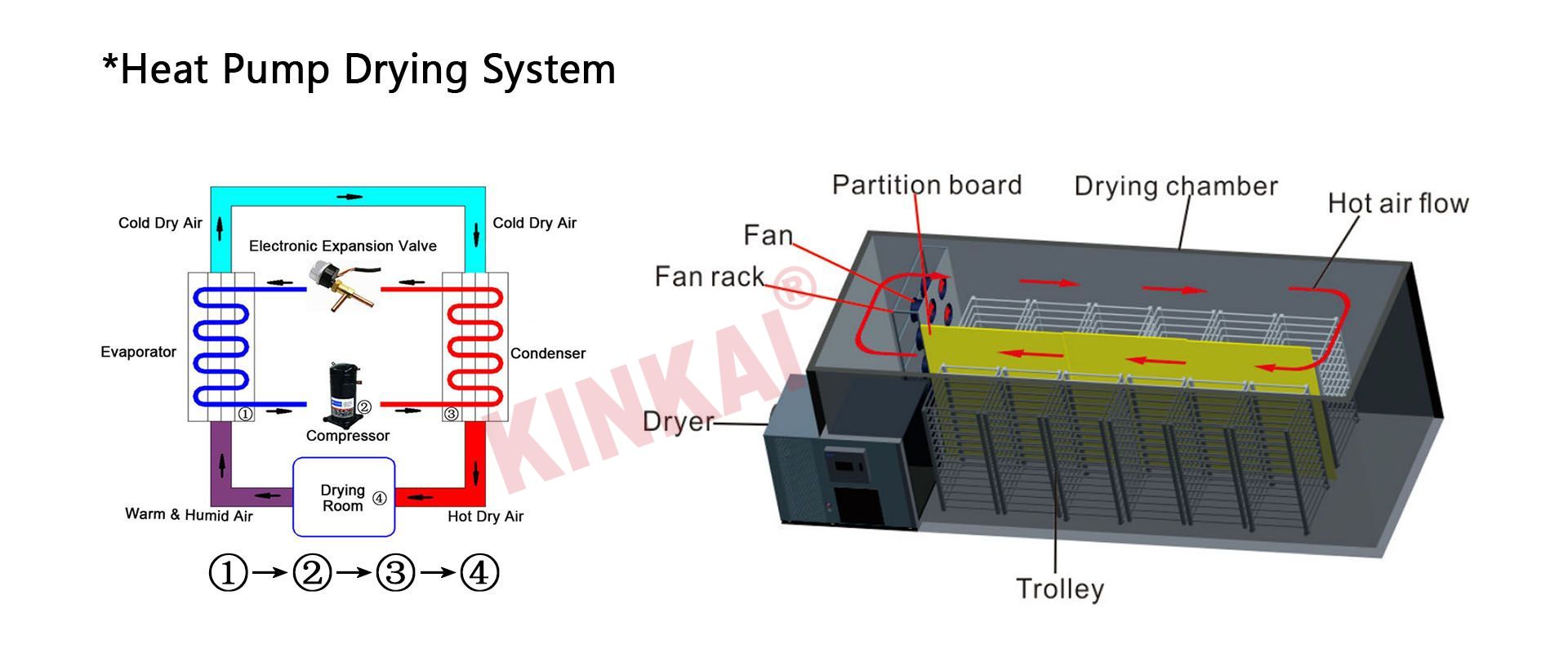

Working Principle of Heat Pump Dryer Machine

Use electric energy to supply power, absorb the air in the surrounding environment through heat pump technology, convert the air source into a heat source, convert 1 kWh of electric energy into 4 parts of air heat energy, save 75% of electricity, and play a high-efficiency, energy-saving, and environmentally friendly role.

Production of Heat Pump Dryer Machine

China’s first heat pump food dryer manufacturer, rich production experience, cost-effective supply chain, stable product quality and excellent after-sales service, providing customers with worry-free purchases.

Loading Heat Pump Dryer Machine-Sea transport

It is packed in a wooden box, stably protects the machine, complete accessories, easy to install, provides installation videos and product instruction manuals, supports online technical support, and can also go to the site to guide installation and use.