How to Dry Mango by KINKAI Heat Pump Dehydrator Machine?

| Application | Fruits/Vegetabless/Agriculturals/Herbs/Seafoods/Meat/Wooden… |

| Power | 220V/380V, 50Hz/60Hz (Customized) |

| Capacity | 100-3500KGS |

| Temperature | 15-75℃ |

| Dehydration Capacity | 6-120L/H |

| Advantages | * 80% Electricity energy saving * Intelligent PLC Control System (Temperature, Humidity, Time) * High drying capacity 100-3500kgs per batch * Easy installation & operation * Widely Application & Customized |

Mango

With succulent pulp, mangoes taste very pleasant, with a mixed flavor of peach, apricot, plum, and apple. In summer, mangoes help to promote fluid production, quench your thirst, clear summer heat, and relax your mind. It is hard to keep them fresh and to transport them for a long distance. We typically can them or cure them into preserved fruit, fruit wine, dried fruit, jam, or jelly.

How to Dry Mango by KINKAI Heat Pump Dehydrator Machine?

Select fresh ripe mangoes: Lv Song mango, ZiHua mango, and wild mangoes grown in Hainan are suitable for processing. Full pulp contributes to the rate of finished products. It would be better that mangoes are nearly ripe. If the maturity is low, mangoes taste bad with poor color. They are perishable in case of post-maturity.

Washing: Put mangoes in the tank, rinse them with clear water flow, select unqualified ones, and put qualified ones in the plastic

baskets by size, and strain water.

Peeling: Use a stainless steel knife to remove the exocarp and by hand. Make sure the surface is smooth and even and all exocarp is removed. If not, the tannin in the exocarp makes it easy to get brown in the process, which hurts the color of finished products. Use a sharp blade to cut peeled mangoes into slices on a vertical basis. Each slice is 8-10 mm thick. The kernel still with some pulp can be made into juice.

Color protection: Use sulfur to smoke or soak slices to protect their color.

Drying: Put the mango slices on the rack (if soaked with sulfur, strain water first), and put the rack in the cabinet to dry the

mango slices up.

At the beginning, the temperature shall be held at 70-75 ° C. In the later phase, the temperature shall be at 60-65 ° C. Pay attention to turning over and rewetting in the drying process.

Softening and packaging: If the moisture content of mango slices meets the desired level, typically 15-18%, put them in the closed

container for 2-3 days to soften them and make water balanced for packaging.

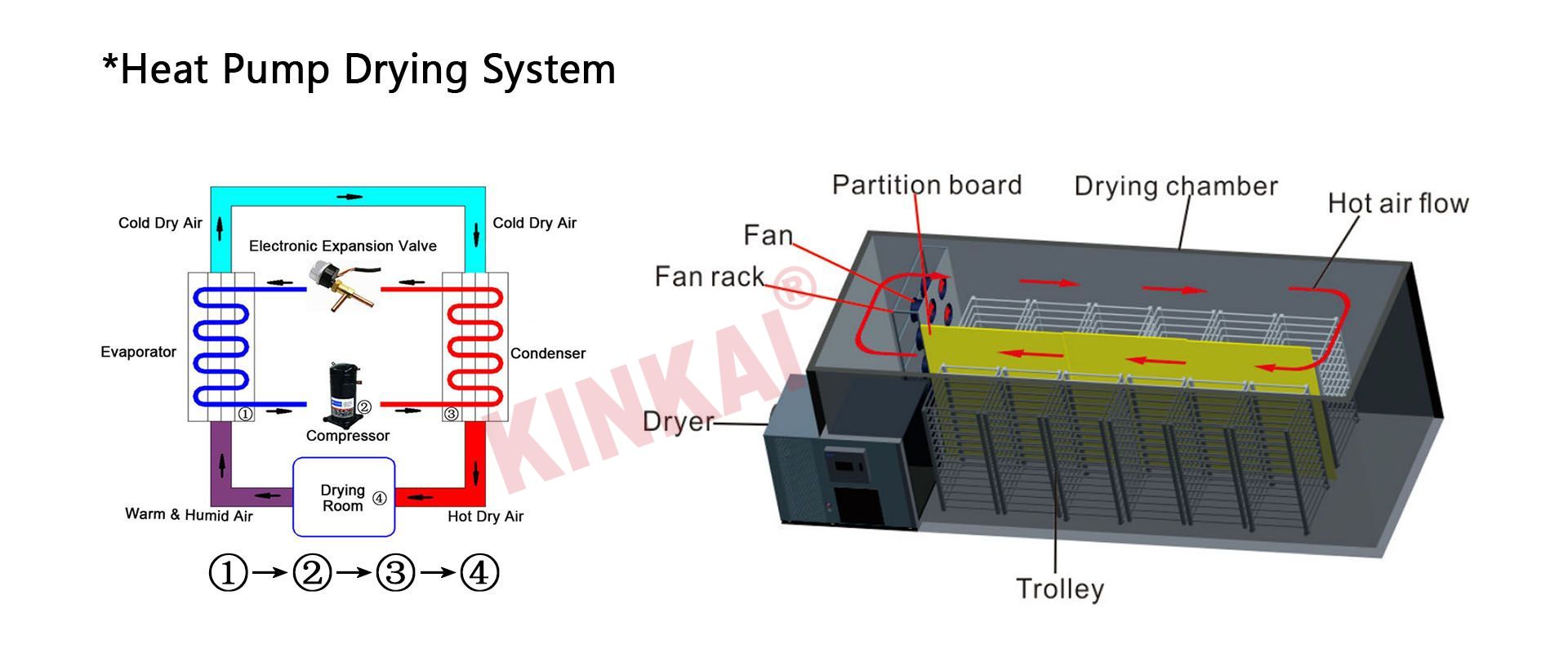

Working Principle of Heat Pump Dryer Machine

Use electric energy to supply power, absorb the air in the surrounding environment through heat pump technology, convert the air source into a heat source, convert 1 kWh of electric energy into 4 parts of air heat energy, save 75% of electricity, and play a high-efficiency, energy-saving, and environmentally friendly role.

Production of Heat Pump Dryer Machine

China’s first heat pump food dryer manufacturer, rich production experience, cost-effective supply chain, stable product quality and excellent after-sales service, providing customers with worry-free purchases.

Loading Heat Pump Dryer Machine-Sea transport

It is packed in a wooden box, stably protects the machine, complete accessories, easy to install, provides installation videos and product instruction manuals, supports online technical support, and can also go to the site to guide installation and use.