How to Dry Purple Chinese Yams by KINKAI Heat Pump Dehydrator Machine?

| Application | Fruits/Vegetabless/Agriculturals/Herbs/Seafoods/Meat/Wooden… |

| Power | 220V/380V, 50Hz/60Hz (Customized) |

| Capacity | 100-3500KGS |

| Temperature | 15-75℃ |

| Dehydration Capacity | 6-120L/H |

| Advantages | * 80% Electricity energy saving * Intelligent PLC Control System (Temperature, Humidity, Time) * High drying capacity 100-3500kgs per batch * Easy installation & operation * Widely Application & Customized |

Purple Chinese Yams

Purple Chinese Yams, the latest species bred by Ziyu Huaishan Vegetables Scientific Institute, have the name for their purple-red pulp. Compared with common white Chinese yams, purple Chinese yams are rich in nutrients such as starch, sugar, and zinc they are good for the eyes and can prevent heart attacks and cancers. They taste good and abound in more than 20 nutrients including starch, sugar, protein, saponin, amylase, choline, amino acid, vitamins, calcium, iron, and zinc. They have become the best among new-generation healthy foods.

How to Dry Purple Chinese Yams by KINKAI Heat Pump Dehydrator Machine?

Temperature-raising phase: Tile-sliced yams on drying racks and push them into the drying cabinet. Start the dryer to send warm wind into the cabinet to raise the temperature to 50° C for 0.5– 1.5 hours. Start moisture removal function when humanity rises. KINKAI heat pump drying and dehumidifying machine can keep the constant temperature over the moisture removal.

Drying and moisture-removing phase: There are two sub-phases, high humanity and low temperature, and medium humanity and medium temperature.

In the first sub-phase

Remove the moisture when the temperature ranges from 40° C to 50° C to avoid the color of yams changing due to high temperature and high humanity. Watch water vapor on the surface of yams so as to remove it at any time. This phase shall last 3-3.5 hours.

In the second sub-phase

The temperature ranges from 50°C to 60°C. If necessary, use fresh air to remove moisture based on the density of moisture.

Speed-reducing and shaping phase (also known as a low-humanity and high-temperature phase): the temperature ranges from 60° C to

70°C . In the first half phase, the temperature shall not be higher than 70°C. In the second half phase, the temperature shall be not lower than 75°C. The whole phase lasts 5-7 hours.

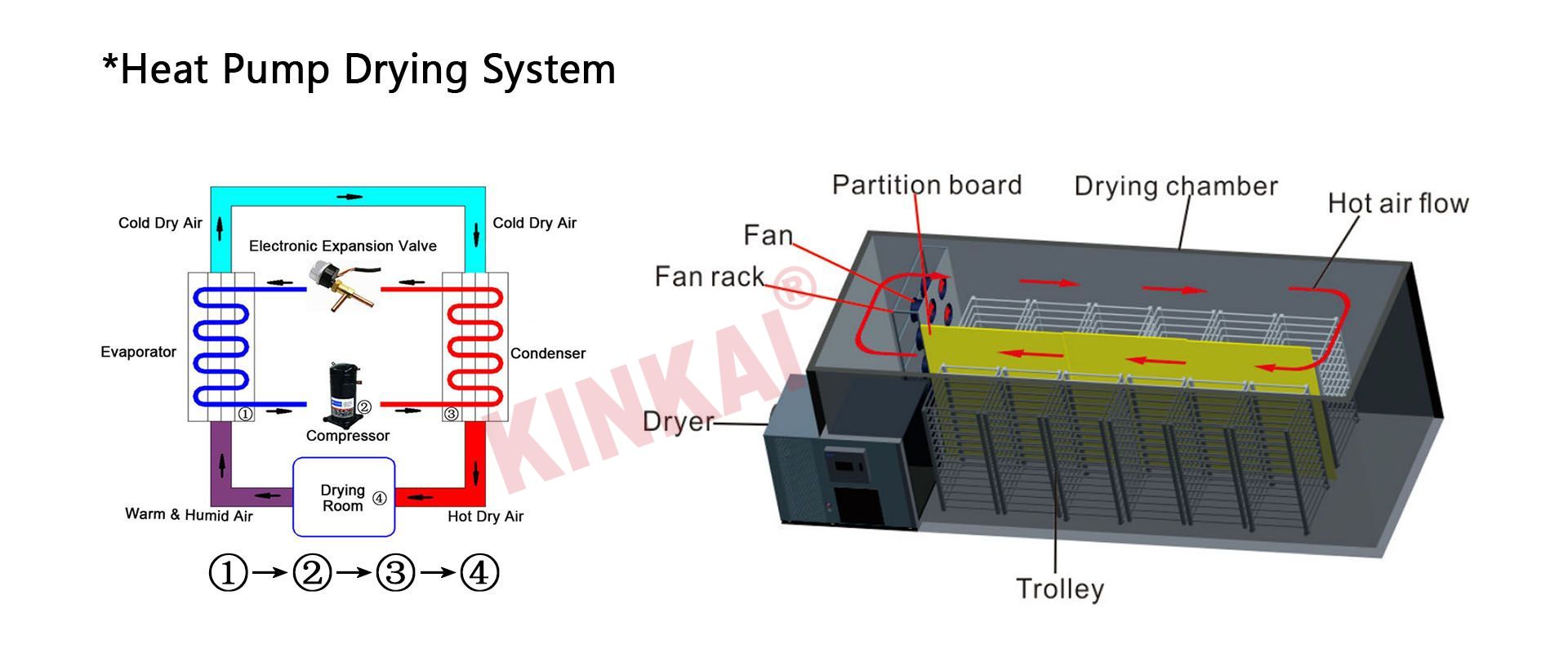

Working Principle of Heat Pump Dryer Machine

Use electric energy to supply power, absorb the air in the surrounding environment through heat pump technology, convert the air source into a heat source, convert 1 kWh of electric energy into 4 parts of air heat energy, save 75% of electricity, and play a high-efficiency, energy-saving, and environmentally friendly role.

Production of Heat Pump Dryer Machine

China’s first heat pump food dryer manufacturer, rich production experience, cost-effective supply chain, stable product quality and excellent after-sales service, providing customers with worry-free purchases.

Loading Heat Pump Dryer Machine-Sea transport

It is packed in a wooden box, stably protects the machine, complete accessories, easy to install, provides installation videos and product instruction manuals, supports online technical support, and can also go to the site to guide installation and use.